Air Blown Fiber Unit MM OM4 EPFU 2~12 core

Technical Specifications

Air Blown Fiber Unit (ITU-T OM4 Fibers)

Technical Specifications for Optical Fiber Cable

1. General

1.1 This specification covers the requirements of the enhanced performance fiber unit to be supplied to customer for installation by blowing.

1.2 The optical fiber cable shall comply with the requirements of this specification and generally meet or better latest

standards:

ITU-T G.650: Definitions and test methods for linear, deterministic attributes of single-mode fiber and cable

ITU-T G.652.D: Characteristics of a single-mode optical fiber and cable

ITU-T G.657: Characteristics of a bending loss insensitive single mode optical fiber and cable for the access network

IEC 60793-2-50 B1.3: Sectional specification for class B single mode fibers

IEC 60793-2-10 A1: Sectional specification for category A1 multimode fibers

IEC 60794-1-2: Optical Fiber Cables, Part 1-2, Generic Specifications-Basic optical cable test procedures General guidance

IEC 60794-1-21: Optical fiber cables, Part 1-21, Generic specification - Basic optical cable test procedures - Mechanical tests methods

IEC 60794-1-22: Optical fiber cables, Part 1-22, Generic specification - Basic optical cable test procedures - Environmental test methods

2. Optical Fiber Characteristics

The optical, geometrical, mechanical and environment characteristics of the ITU-T OM4 optical fiber shall be accordance with below table:

| Characteristics | Specified Values | Units | |

| Optical Characteristics | |||

| Attenuation coefficient | at 850nm | ≤3.5 | dB/km |

| at 1300nm | ≤1.5 | dB/km | |

| Bandwidth (OFL) | @ 850nm | ≥3500 | MHz.km |

| @ 1300nm | ≥500 | MHz.km | |

| Attenuation non-uniformity | ≤0.1 | dB | |

| Zero dispersion wavelength ( λ0) | 1320 ~1365 | nm | |

| Dispersion coefficient | @ 1295 ~ 1310nm | £ 0.11 | ps/(nm·km) |

| @ 1310-1340nm | £0.001(1458-l0) | ps/(nm·km) | |

| Effective group index of refraction (Neff) | at 850nm | 1.496 | - |

| at 1300nm | 1.491 | - | |

| Numerical aperture | 0.275± 0.015 | - | |

| Geometric characteristic | |||

| Core diameter | 62.5 ± 2.5 | µm | |

| Core non-circularity | ≤5.0 | % | |

| Cladding diameter | 125.0±1.0 | µm | |

| Cladding non-circularity | ≤1.0 | % | |

| Coating diameter | 245±10.0 | µm | |

| Coating-cladding concentricity error | ≤12.0 | µm | |

| Coating non-circularity | ≤6.0 | % | |

| Core-cladding concentricity error | ≤1.5 | µm | |

| Mechanical characteristic | |||

| Proof stress | ≥0.69 | GPa | |

| Coating strip force | Average value | 1.0-5.0 | N |

| Peak value | 1.3-8.9 | N | |

| Macro bending loss | Ф75mm, 100 circles, at850nm | ≤0.5 | dB |

| Ф75mm, 100 circles, at 1300nm | ≤0.5 | dB | |

3. Characteristics of Cable

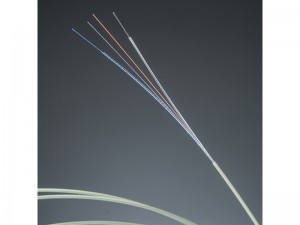

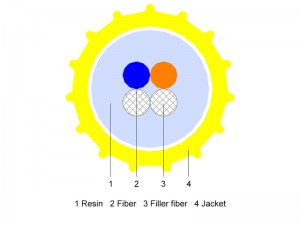

3.1 Cable Construction and Parameter3. Characteristics of Cable

The resin coated optical fibers, and outer sheath extruded on the tight buffer.

| Items | Descriptions | |||||

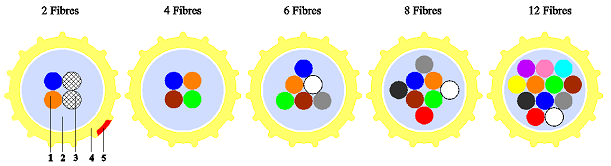

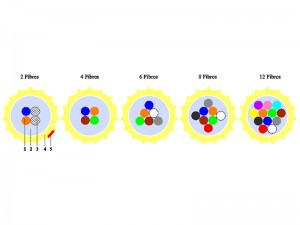

| Optical fiber | 2F | 4F | 6F | 8F | 12F | |

| Outer sheath | Material | Natural HDPE | ||||

| Cable nominal diameter(±0.05mm) | 1.15mm | 1.15mm | 1.35mm | 1.55mm | 1.65mm | |

| Cable approx. weight (kg/km) | 1.0 | 1.0 | 1.2 | 1.5 | 1.8 | |

| Max. tensile strength | Short time | W*G N | ||||

| Max. crush resistance | Short time | 100N/100mm | ||||

| Minimum Bending radius | Dynamic | 20 times of cable diameter | ||||

| Static | 10 times of cable diameter | |||||

| Temperature range | Installation | -10℃~+40℃ | ||||

| Storage | -20℃~+60℃ | |||||

| Operation | -20℃~+60℃ | |||||

| Air Blowing | Equipment: PR140, Duct: 5/3.5mm, Blowing pressure: ≤10bar,Typical blowing length: 1000m | |||||

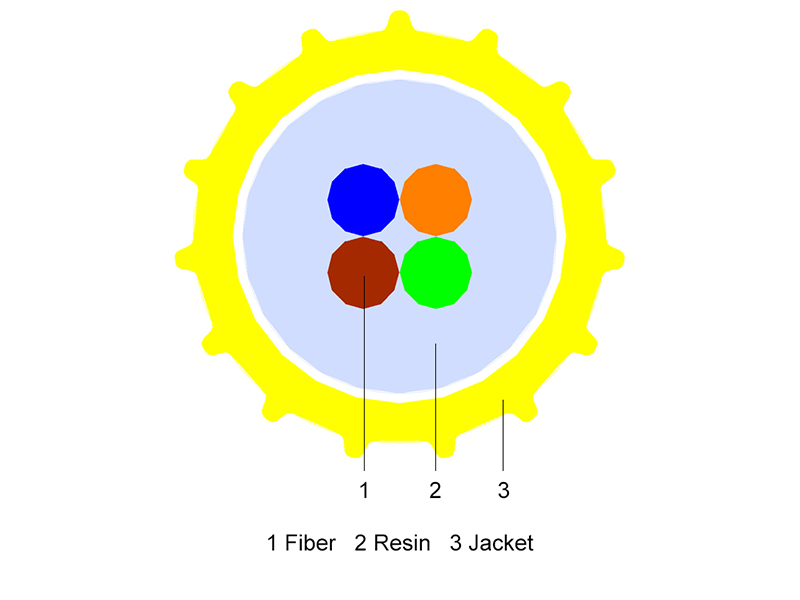

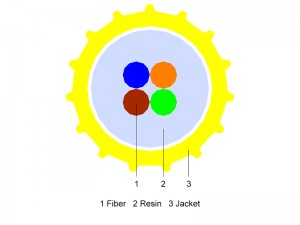

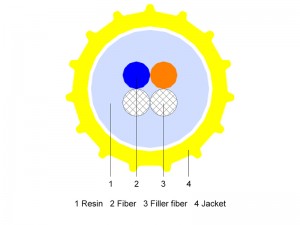

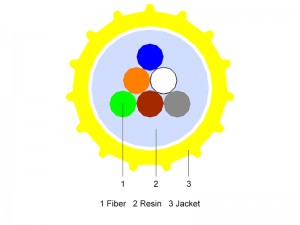

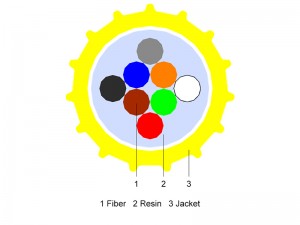

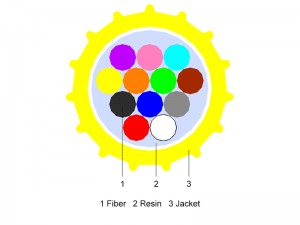

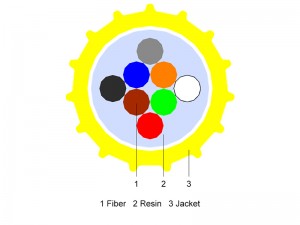

3.2 Cross-section of Cable

1. Optical fiber 2. Resin 3. +2 ‘Filled’ Fibers 4. Groove 5. HDPE sheath

Fiber Color Identification

The individual fiber shall be in accordance with standard TIA/EIA-598-A and the color code as below.

Fiber Colors: Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Purple, Pink, Aqua

Mechanical and Environmental Test

| tem | Details |

| Tensile loading test | Test Method: Accordance with IEC60794-1-21-E1

Tensile force : W*G N Length: 50m Holding time : 1 minutes Diameter of mandrel: 30 x cable diameter After test the fiber and cable no damage and no obvious change in attenuation |

| Crush / Compression test | Test Method: Accordance with IEC 60794-1-21-E3

Test Length: 100 mm Load: 100 N Holding time: 1 minutes Test result: Additional attenuation ≤0.1dB at 1550nm. After test no sheath cracking and no fiber breakage. |

| Cable bending test | Test Method: Accordance with IEC 60794-1-21-E11B

Mandrel Diameter: 65mm Number of Cycle: 3 cycles Test result: Additional attenuation ≤0.1dB at 1550nm. After test no sheath cracking and no fiber breakage. |

| Flexing / Repeated Bending test | Test Method: Accordance with IEC 60794-1-21- E8/E6

Mass of the weight : 500g Bending diameter : 20 x diameter of cable Impact rate : ≤ 2 sec / cycle Number of cycles : 20 Test result: Additional attenuation ≤0.1dB at 1550nm. After test no sheath cracking and no fiber breakage. |

| Temperature cycling test | Test Method: Accordance with IEC 60794-1-22-F1

Variation of temperature : -20℃ to + 60℃ Number of cycles : 2 Holding time per each step : 12 hours Test result: Additional attenuation ≤0.1dB/km at 1550nm. |

Cable Marking

Unless otherwise required the sheath will be use inkjet marked at intervals of 1m, containing:

- Customer name

- Manufacture’s name

- Date of manufacture

- Type and number of fiber cores

- Length marking

- Other requirements

Environmentally

Full comply with ISO14001, RoHS and OHSAS18001.

Cable Packing

Free coiling in the pan.

Standard delivery lengths are 4km with a tolerance of -1%~+3%.